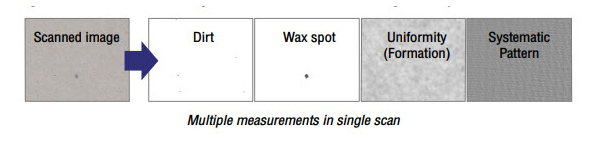

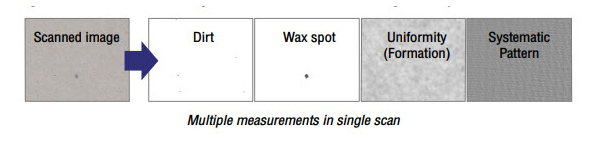

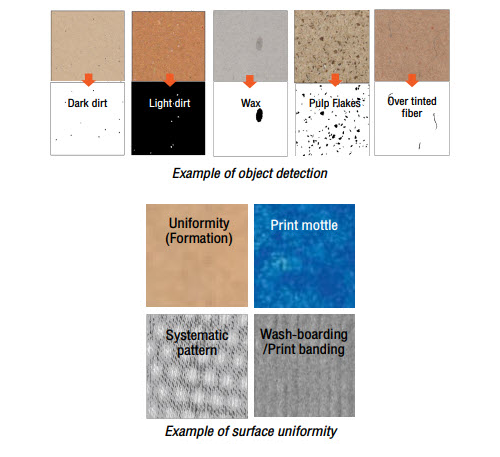

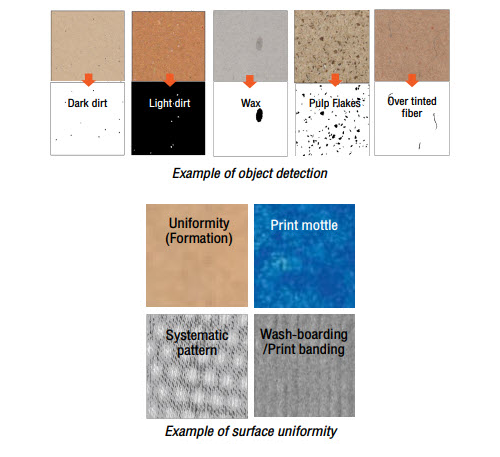

The PRECISEPRO "Versatile Image Analyzer" is a scanner-based image analysis system designed for measuring various paper surface properties within single scan.

Are you looking for support information?

Contact us The PRECISEPRO "Versatile Image Analyzer" is a scanner-based image analysis system designed for measuring various paper surface properties within single scan.

The PRECISEPRO "Versatile Image Analyzer" is a scanner-based image analysis system designed for measuring various paper surface properties within single scan.

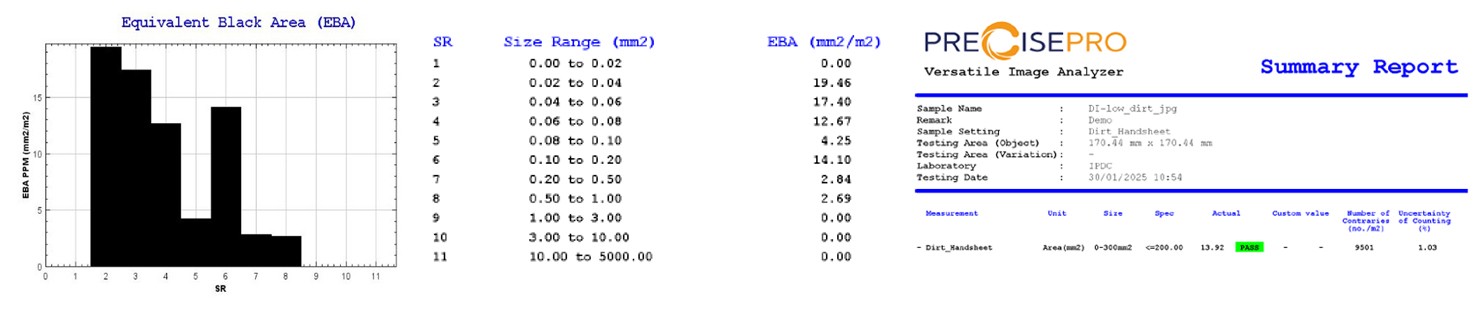

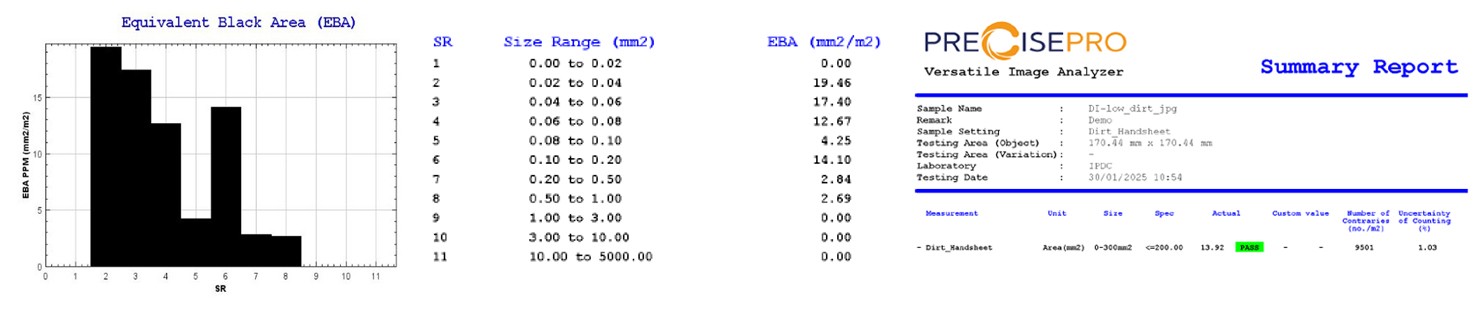

Report (Example)

Report (Example) Report (Example)

Report (Example)